1.800 m3/h - 8 CARTRIDGE

3.600 m3/h - 16 CARTRIDGE

5.400 M3/H - 24 CARTRIDGE

7.200 M3/H - 32 CARTRIDGE

9,000 M3/H - 40 CARTRIDGE

10.800 M3/H - 48 CARTRIDGE

TABLE DIMENSIONS

8-PIECE TABLE - 305X610X60

16 PLATE - 610X610X60

|

Filter Class (EN 1822) |

Odor Treatment |

|

Frame Material |

electrogalvanized steel |

|

Filter Media |

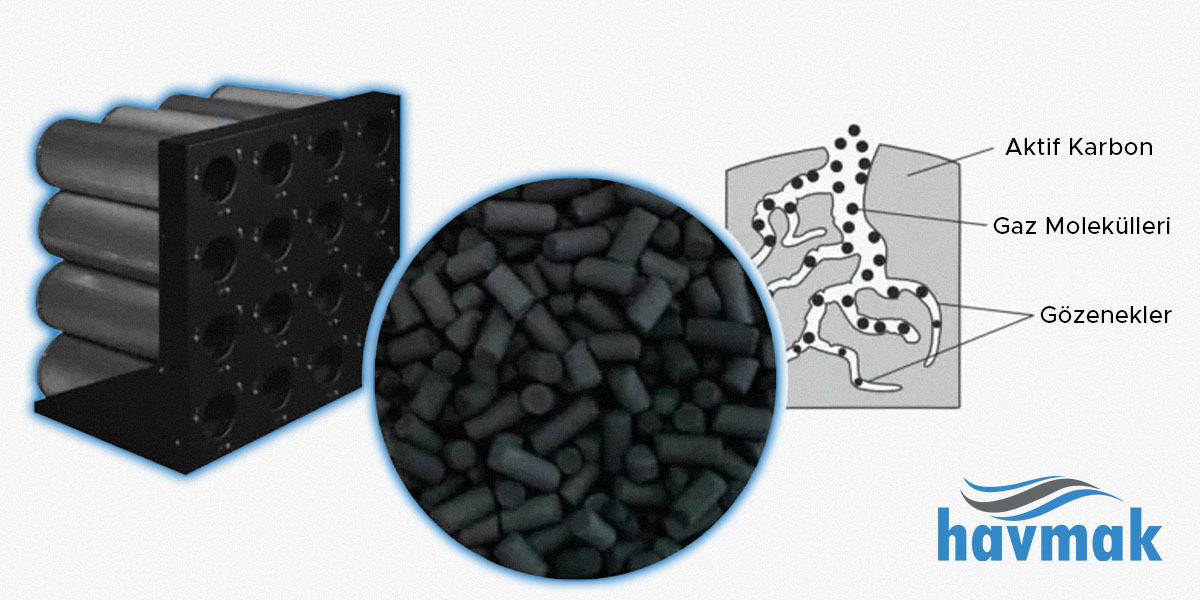

4mm Activated Carbon Pellet |

|

Max. Pressure difference |

400Pa |

|

Cylinder cartridge diameter |

140 – 145mm |

|

Operating temperature |

50 Degrees |

|

Relative humidity |

80% |

Activated carbon filter is a type of filter obtained by activating carbon through a special process. Thanks to its microporous structure, it can effectively adsorb harmful gases and bad odors. These features enable excellent results to be achieved when used in ventilation systems. Carbon particles with increased surface area become a good chemical purifier. 1 gram of activated carbon has a surface area of approximately 600 to 2400 m2.

Where is Active Carbon Filter Used?

Activated carbon filters are used in many areas both in industry and individually. Active carbon filters that provide chemical purification are chemical filters of gases and liquids.

It is a good choice for filtering. It is used in ventilation systems due to its odor trapping properties.

How to Use an Active Carbon Filter?

Activated carbon filters are good odor traps when used with the right technique. What we mean by correct technique is;

Criteria such as are not met.

Does Active Carbon Filter Retain Smoke?

No. Active Carbon Filter cannot filter smoke, oil and dust particles. For such contaminants, an electrostatic filter or, depending on the situation, an oil trap filter should be used.

Direct exposure of the Active Carbon Filter to smoke and oil without using other filters will clog the pores in a short time, making the filter unusable.

How to Clean Activated Carbon Filter?

Activated Carbon Filters have a high surface area due to their structure. Over time, pollutant particles clog these pores and expire the life of the filter.

No washing or cleaning method can reopen these micropores. For this reason, activated carbon filters cannot be cleaned. It requires change.

How Long is the Life of an Active Carbon Filter?

As we mentioned above, filter life will decrease inversely proportional to the filling rate of the pores. As particle accumulation in the pores increases, filter life will decrease.

It is not possible to make an exact and clear prediction for this period. Because the specific particle density of each system varies. In short, how few particles can enter the activated carbon filter?

If purified, oil-free and smoke-free air comes into contact, the filter life will extend accordingly. Under optimum conditions, the lifespan of the activated carbon filter is approximately 12 months.

How to Change Activated Carbon Filter?

Activated Carbon Filters can be produced in many ways depending on the area of use. There are two different ways to use it in the ventilation field: Cylinder Cartridge and Panel Carbon.

The same activated carbon particles undertake the filtering task in both areas of use. Cylinder Cartridge system has advantages such as lower pressure loss and high contact time.

Panel filters can be used in areas where less intense odor filtering is targeted. In both systems, change is achieved by the renewal of the carbon particles in them.

The expired active carbon filter is emptied and reused by adding a new granular active carbon filter.

Is Active Carbon Filter Efficient?

Active carbon filter cannot filter all gases at the same rate. See the table below to see which gases and in what proportion the activated carbon filter can retain.

In this table, you will see numbers from 1 to 4 for each gas. These numbers show the extent to which the filter can capture the mentioned gases.

1-Slight 2-Moderate 3-Satisfactory 4- Very good

| wood alcohol | 3 | Oil | 4 | Naphtha (petroleum) | 4 |

| Air-Wick | 4 | agents of mystery | 4 | Naphthalene | 4 |

| acrylic acid | 4 | Fertilizer | 3 | Naphthalene | 4 |